Brewing a Stout + Condensation Test

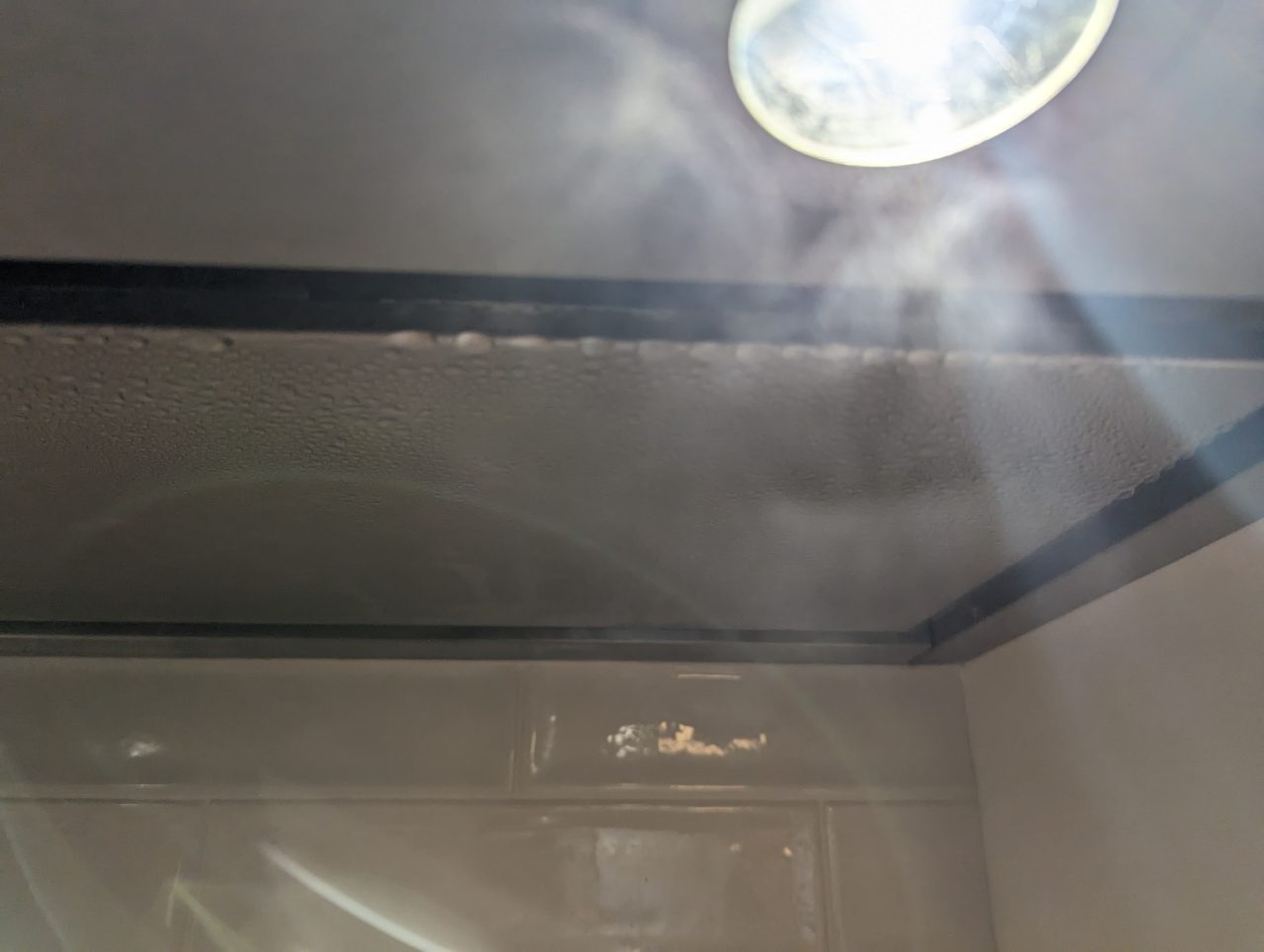

The condensation on the range hood in the brewing space is the one major issue with the space that I'd like to resolve, but before replacing the range hood with a condensation hood, I wanted to do a test batch in the kitchen in the house to see if the behavior was similar.

Certainly stock kitchen range hoods are more designed for grease and smells than they are for heat and condensation, but I wanted to at least see if the relatively inexpensive range hood I installed in the brewing space just isn't that great, and since the one in the kitchen in the house is much nicer and also vents out the back, it seemed like a decent thing to at least try.

For this experiment I brewed a simple one-gallon all-grain Irish Stout kit from SoCo Homebrewing using the Gigawort since that's typically what I use out in the brewery.

The brewing process went as per usual though I did notice the Gigawort being more loose with keeping the temperature to the set level than usual. One of the complaints I've read about this unit, which I've also experienced, is that it can let the temperature drift down as much as 5 or 6 degrees before kicking on the heating element.

Now I'm not one to get totally hung up on having the exact mash temp for the entire hour of the mash -- not that it's not important, but drifting a bit doesn't make or break a batch in my experience -- but by the time it's dropping several degrees and catching back up, you're spending a not insignificant portion of the mash time at sub-optimal temperatures.

Might be time to move back to a kettle and induction cooktop for these smaller batches (which I've had great luck with), or throw the sous vide back in the mix, and then look into getting a small Anvil Foundry for larger batches. But that's a problem for another day.

After the 60-minute mash it was time to start the boil, and everything was going well. For a while anyway.

After boiling for about 15 minutes or so, I had my answer about the condensation.

So it's looking like I have a condensation hood in my future for the brewery. Which is fine, other than the expense of course, but it's going to significantly improve the quality of my brew days not to have to constantly wipe down the range hood or risk condensation dripping back into the brew kettle.

Condensation Hood Challenges

The issue with trying to find a condensation hood that will fit in my existing space -- approximately 30" wide -- is that most condensation hoods are for commercial kitchens so they're huge and quite expensive.

Pretty much the only place I've found that will do one in a size that will work is Fast Kitchen Hoods. They make the hood itself to your specs so it can be more or less any size, which will work great for replacing my existing hood since not only will it fit in the space, but they can place the exhaust port in the right spot for me to use my existing roof vent.

HoodMart also seemed semi-promising since they seem to let you use their "hood builder" wizard to get a quote, but I've filled that thing out twice now and never get a response. I'm also not convinced they make one as small as I'd need since when I put my size in the form the size changes to 36" when you go to the next step.

And yeah, I could rethink my upper cabinets and install a larger hood, but for the scale of brewing I do a 30" hood will be absolutely adequate. I just want something that doesn't drip.

Or, I could build one myself. I've seen some people build condensation hoods themselves and while I'm not averse to DIYing things, the hood project just isn't something I'm interested in taking on as a build project at this point.

I've also been reading about steam condensing lids like this one from Spike and while that's another way to solve the problem, my hangups with this solution are two-fold: First, these would be tied to a particular kettle and I really love having flexibility in the kettle I use to brew based on the size and other factors in each batch; and second, it seems like this would add a ton of complexity to my setup. I want to throw stuff in a kettle, throw some heat on it, and make beer, and the steam condensing lid approach seems like an inflexible, Rube-Goldbergian approach when compared to just getting a hood that's decoupled from the kettle to handle the condensation. (I mean seriously, I watch this video and it reminds me of this scene from the brilliant show "Patriot" and the classic "Turbo Encabulator" video. I just wanna make some beer!)

All that said, with the experiment brewing under another range hood completed my plan at this point is to move forward with Fast Kitchen Hoods since they can build one that'll be as much of a drop-in replacement for my current hood as I'll be able to find. It also helps that their sales support has been SUPER responsive and helpful in answering my questions thus far.

I also want to say thanks to the folks who run The Electric Brewery website since that's how I stumbled across Fast Kitchen Hoods.

Back to the Beer

All my first-world condensation problems aside, the brew day came off without a hitch though the change in location did necessitate some improvisation.

Running a hose from the back porch to the wort chiller

Running a hose from the back porch to the wort chiller

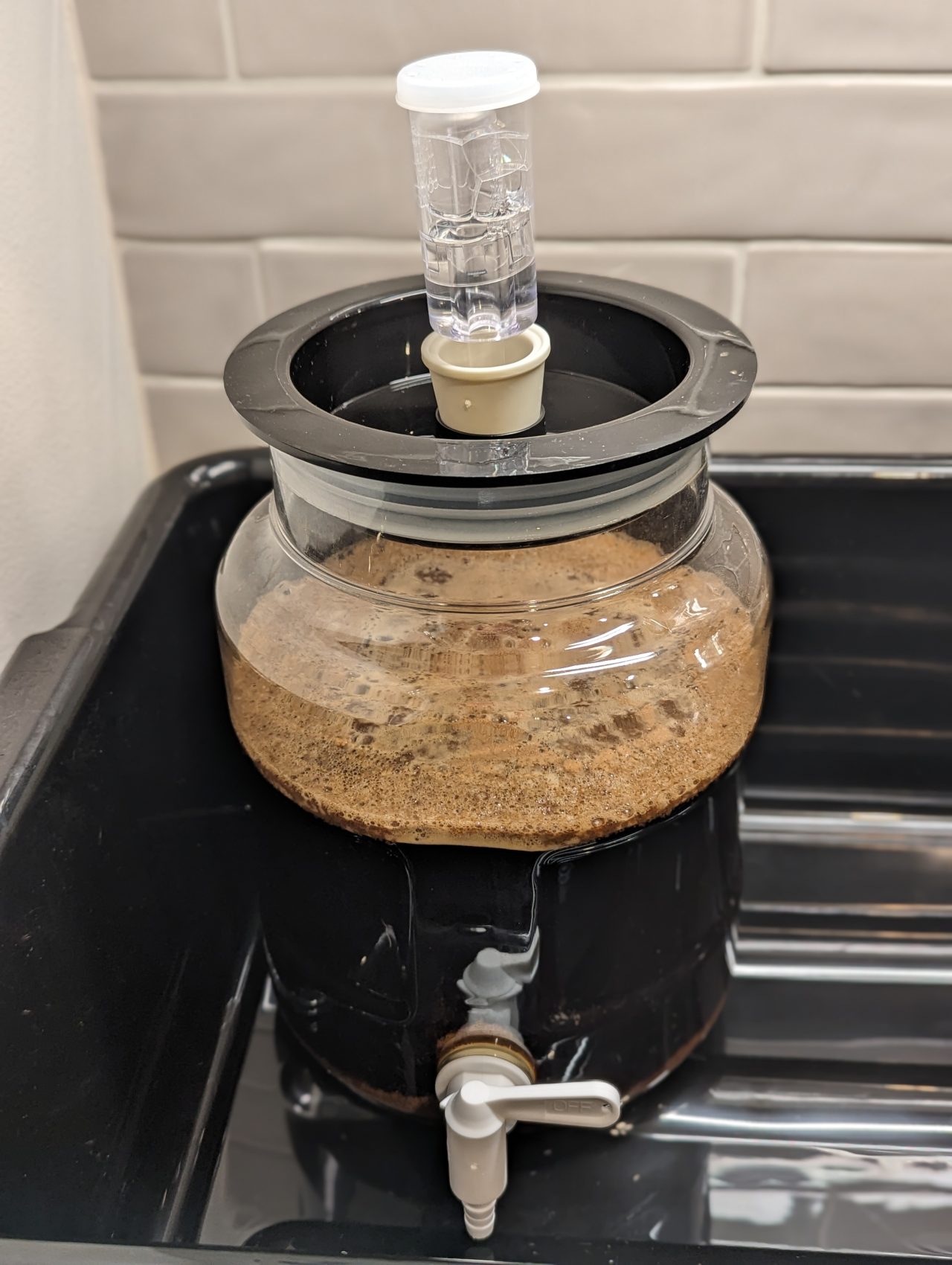

And within a few hours, the beer seems happy.

Four hours after pitching

Four hours after pitching

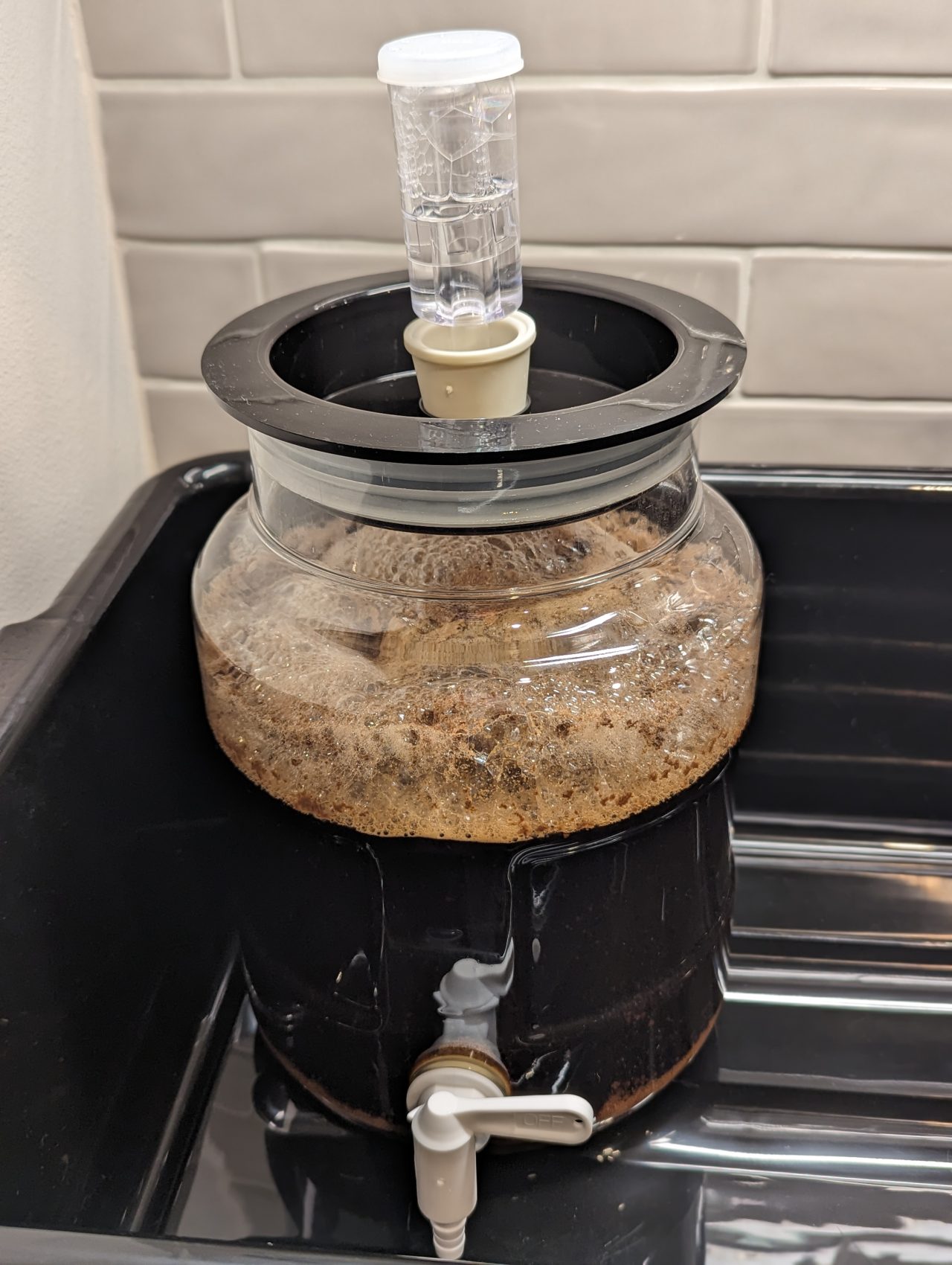

Seven hours after pitching

Seven hours after pitching

And now the worst part of brewing: we wait.